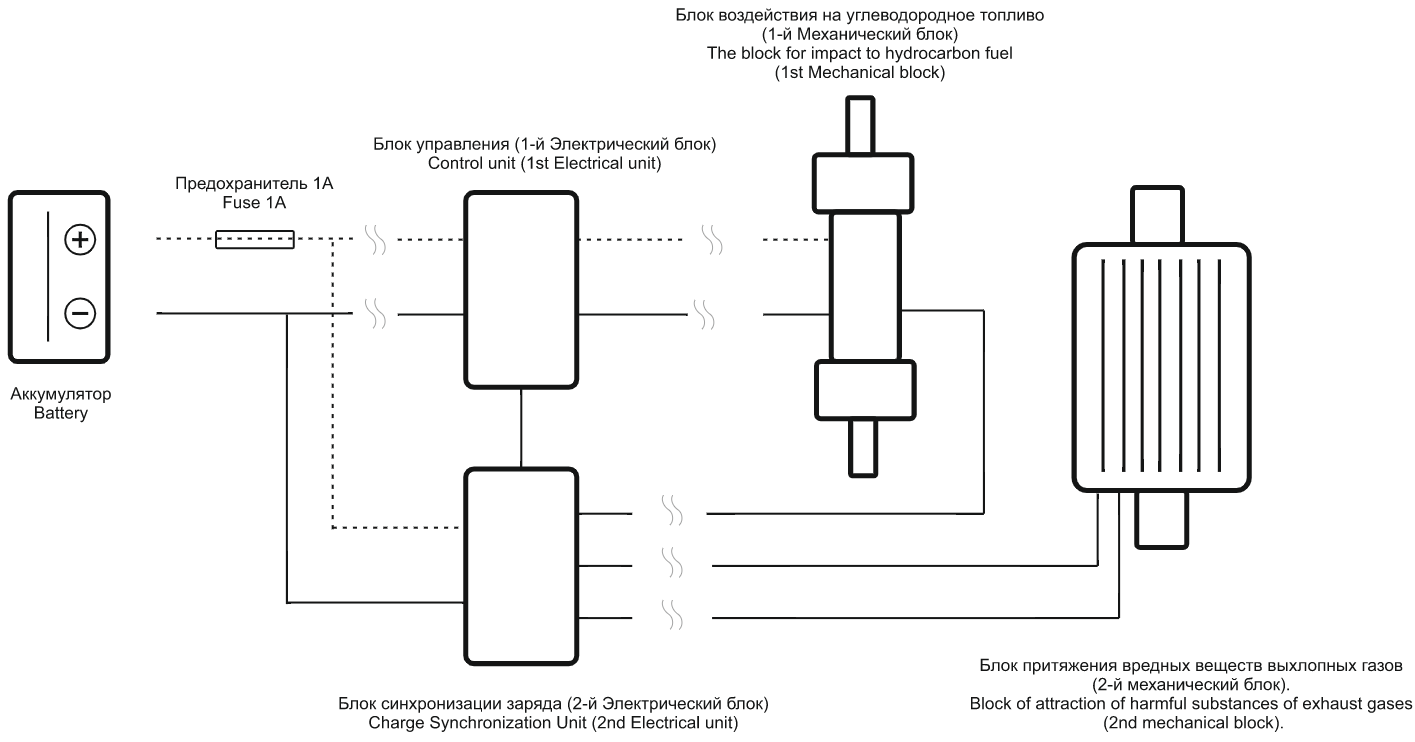

Composition of the device complex

The technology works on the principle of high-voltage radio frequency resonance.

The technology includes a set of devices installed on a vehicle in order to reduce the amount of harmful exhaust gases of an internal combustion engine to zero, while improving fuel economy and engine power.

The complex consists of interconnected devices:

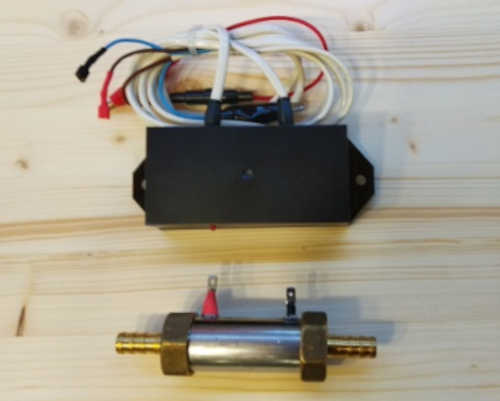

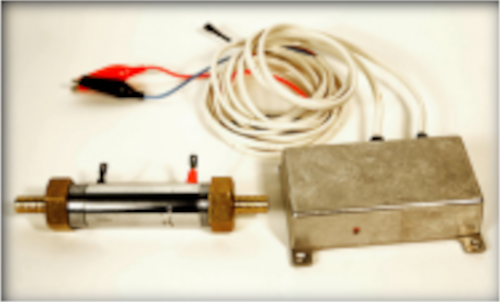

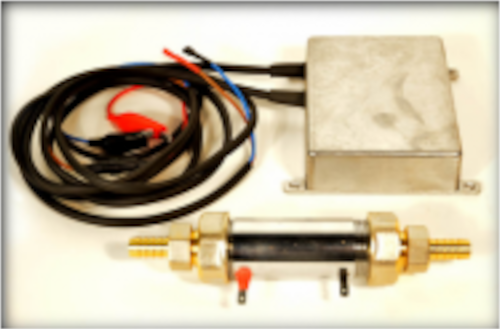

Control unit (1st electrical unit)

Block of influence on hydrocarbon fuel (1st mechanical block)

Charge Synchronization Unit (2nd Electrical Unit)